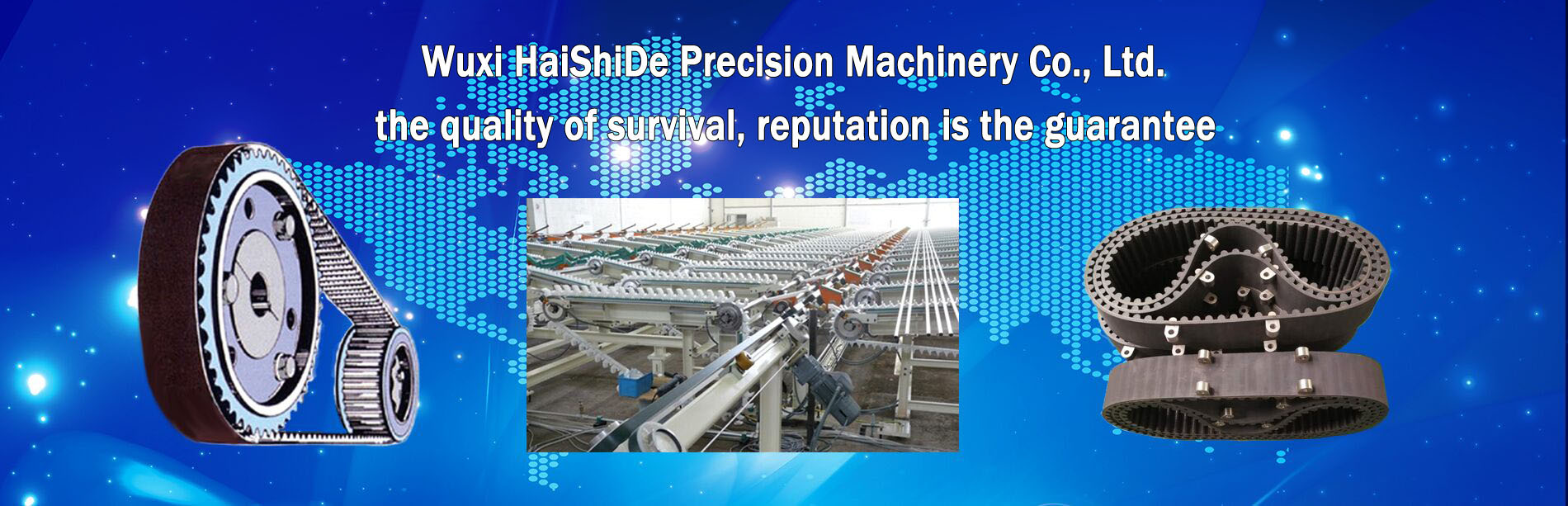

Double Chain Wheel

- Product introduction

Chain transmission is through the chain sprocket with special tooth movement and transfer the power to a drivesprocket tooth profile with the special. Chain transmission has many advantages, compared with the belt drive, noelastic slip and skid phenomenon, the average transmission ratio accurate, reliable work, high efficiency; large transmission power, strong overload capacity, transmission size under the same conditions; the tension force,acting on the shaft of the pressure is small, can be in high temperature; moisture, dust, pollution and other harsh environments. The main disadvantages are: chain drive can only be used for transmission between two parallel axes; the cost is high, easy to wear, easy extension, the transmission stability is poor, it will generate additional dynamic load, vibration, shock and noise, should not be used in the transmission of the rapid reverse.

Sprocket tooth profile on both sides are circles, in order to facilitate the link to enter and exit the meshing. Tooth shape processing using standard tools, the sprocket working drawing without draw end teeth, but to draw thesprocket tooth profile sprocket bad hair cut, to ride. See the design manual specific size axial tooth profile.Sprocket tooth should contact with enough strength and wear resistance, so the tooth surface by heat treatment.The number of the small sprocket meshing than the big sprocket, the impact force is large, the materials usedshould be better than the big chain wheel. Wheel material commonly used are carbon steel (such as Q235, Q275,45, ZG310-570), grey cast iron (HT200) etc.. The chain wheel can be made of alloy steel. The smaller diameter sprocket can be made into solid medium; chain wheel diameter can be made into a hole plate type sprocket; large diameter can be designed into a combined type, if the gear failure due to wear, can change the gear ring.Sprocket hub portion size can be reference of belt wheel.