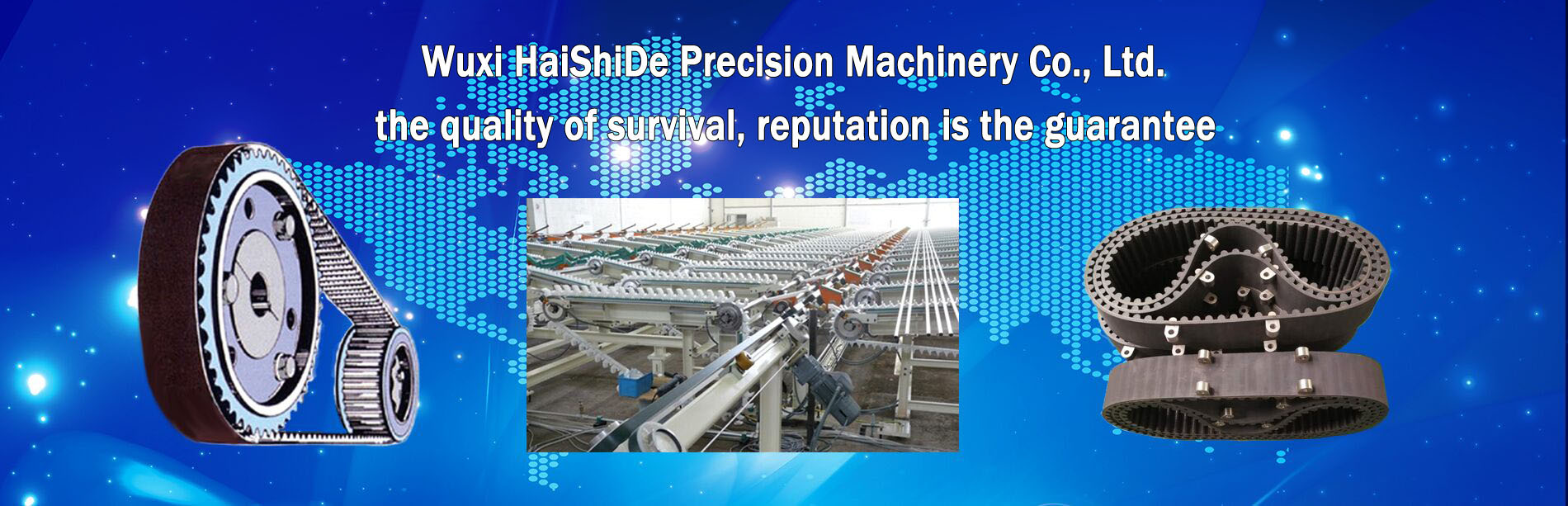

Accurate placement of the synchronous belt, synchronous belt wheel

Accurate placement of the synchronous belt, synchronous belt wheel

(1) turn off power, remove the protective cover, unscrew the screw motor device. Move the motor belt enoughslack, not necessary open can remove the synchronous belt, do not put the belt broken down.

(2) remove the old belt, check whether there is very wear probably means problems of transmission plan ortreatment.

(3) with the belt replacement.

(4) clean the belt and the synchronizing wheel, the cloth stained with a little less volatile liquid cleaning agent for about, in a clean wash by clean agent belt are not taken. To remove the oil and dirt, sand or sharp objectsscratching, obviously is not taken. The belt must be connected in the dry place.

(5) check the synchronous belt wheel are very worn or cracked, if excessive wear, you must replace the belt wheel.

(6) check the belt wheel is a linear symmetric. The pulley into linear symmetrical to the transmission belt especiallysynchronous belt transmission device running the crucial. (see Figure 1)

(7) check the other parts of the device, such as the symmetry of the bearing and the bearing sleeve, durability and lubrication conditions etc..

(8) for the new belt on the pulley, not to pry or violently.

(9) tightening drive central distance, until the tension measuring instrument measured the belt tension properly.Automatic hand wheel rotation test, tension.

(10) device of bolt tightening torque motor, correction. Since any change in urban driving device in operation due to poor performance of the central distance of belt, it must ensure that all transmission parts have been tightening.

(11) the starter and inspect the belt performance, observe whether there is vibration, listen to whether there isnoise. The best time is off, check the bearing and motor status: if feel that too, is probably the belt is too tight, orbearing different errors, inaccuracies or lubrication.